Lemezteszter

Research and Development of Intelligent Optical Sheet Metal Part Recognizer and Laser Marking Device

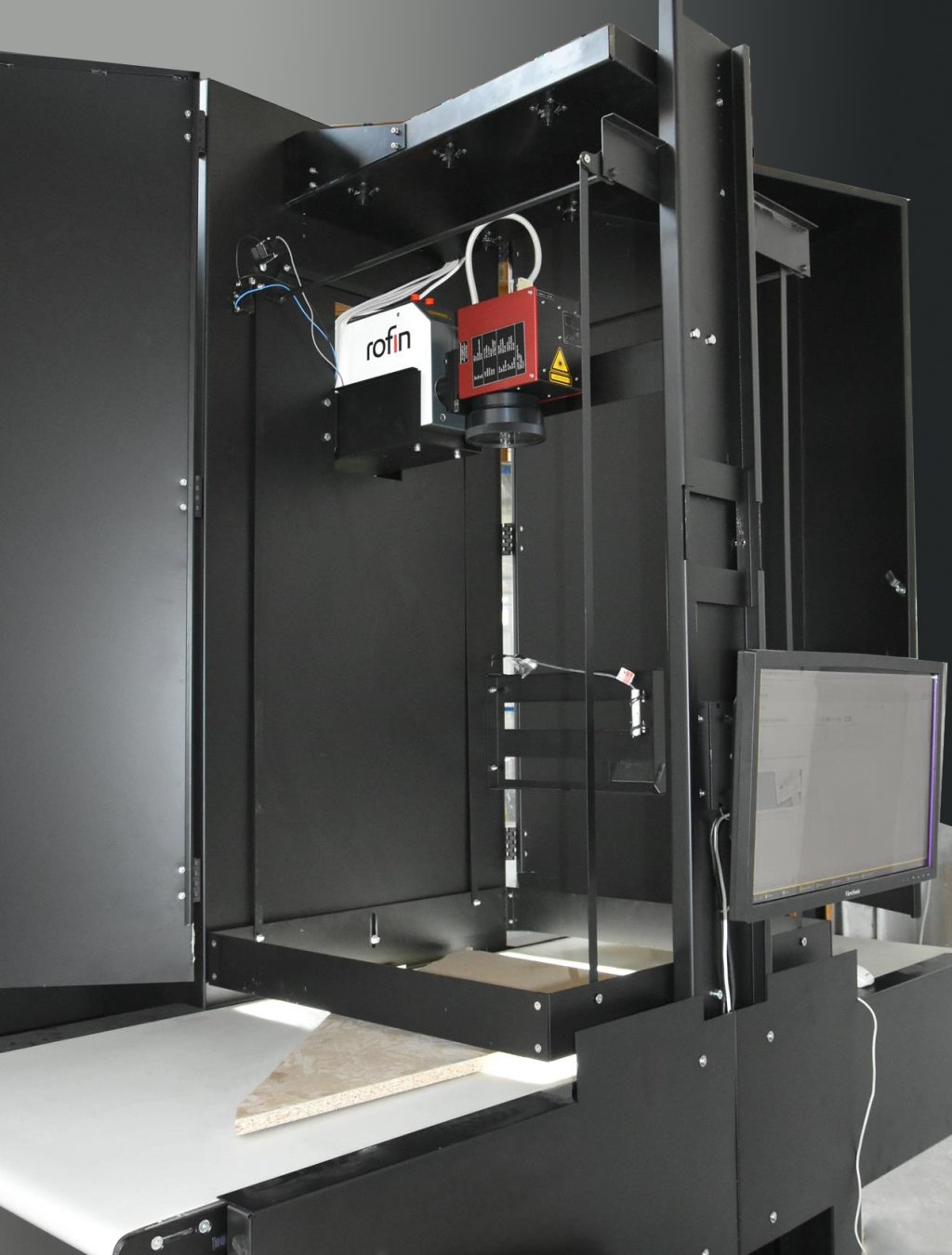

A new, domestically developed system capable of automating quality control tasks for companies dealing with sheet metal parts in both small- and large-scale production environments. The new system, jointly developed by Meleghegyi és Társa Kft. and Optimal Optik Kft., will not only check the weight, material thickness, external dimensions, and contour of the finished sheet metal products but will also engrave the appropriate serial number or code into the sheet.

Objective

Meleghegyi és Társa Kft. is developing a fundamentally new tool for sheet metal manufacturing. In cooperation with Optimal Optik Kft., the company is automating quality control in sheet metal manufacturing. The project titled "Research and Development of Intelligent Optical Sheet Metal Part Recognizer and Laser Marking Device" and the resulting new device will revolutionize the previously manual work. The process, which previously involved human measurements and numerous error possibilities, can now be fully automated. This is particularly significant when, as is common in the lives of manufacturers, multiple orders for different parts are being produced simultaneously. Human inspectors can easily get confused, and their work becomes very stressful, but the machine does not care in what order the various parts arrive, explains László Meleghegyi, the company owner.

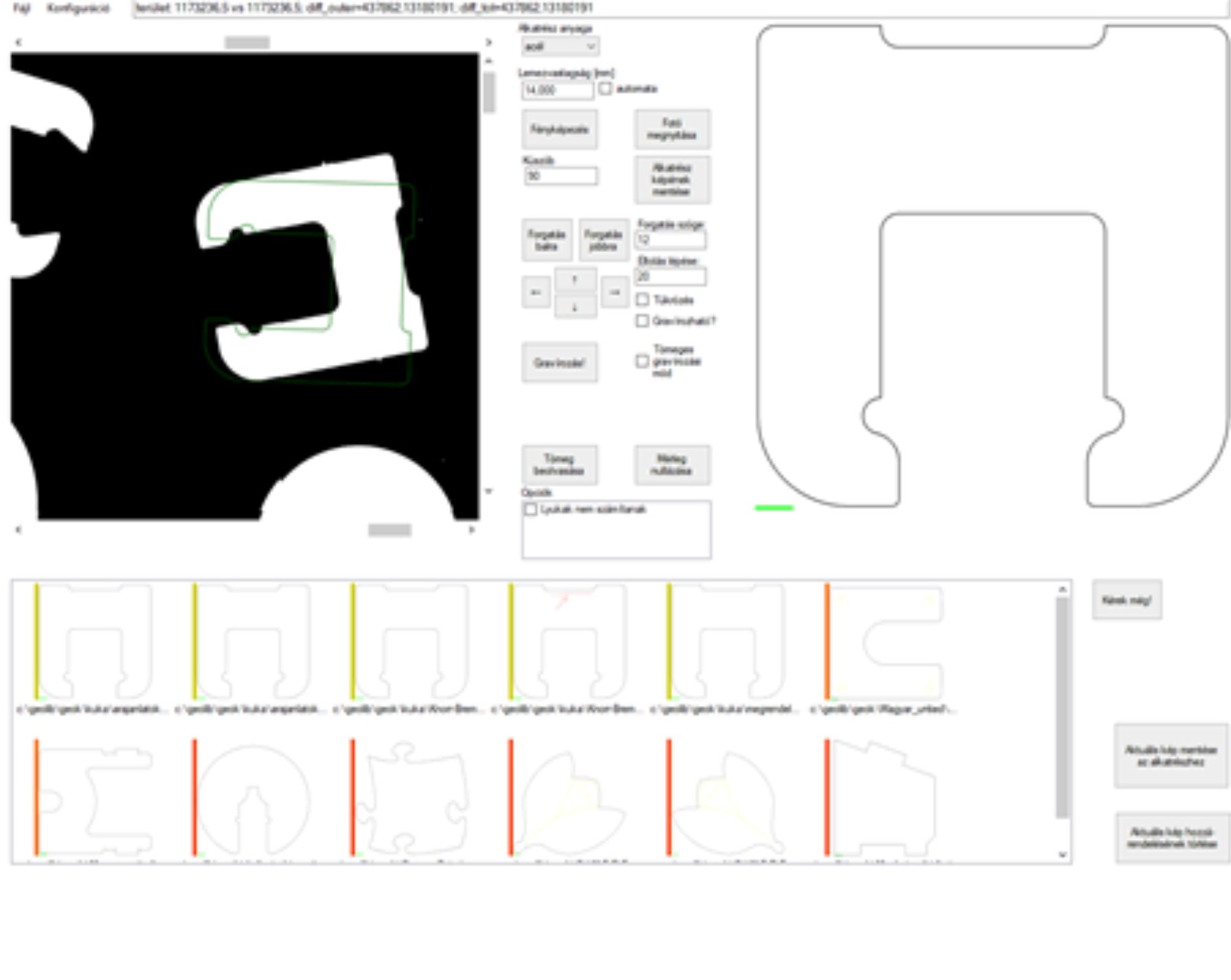

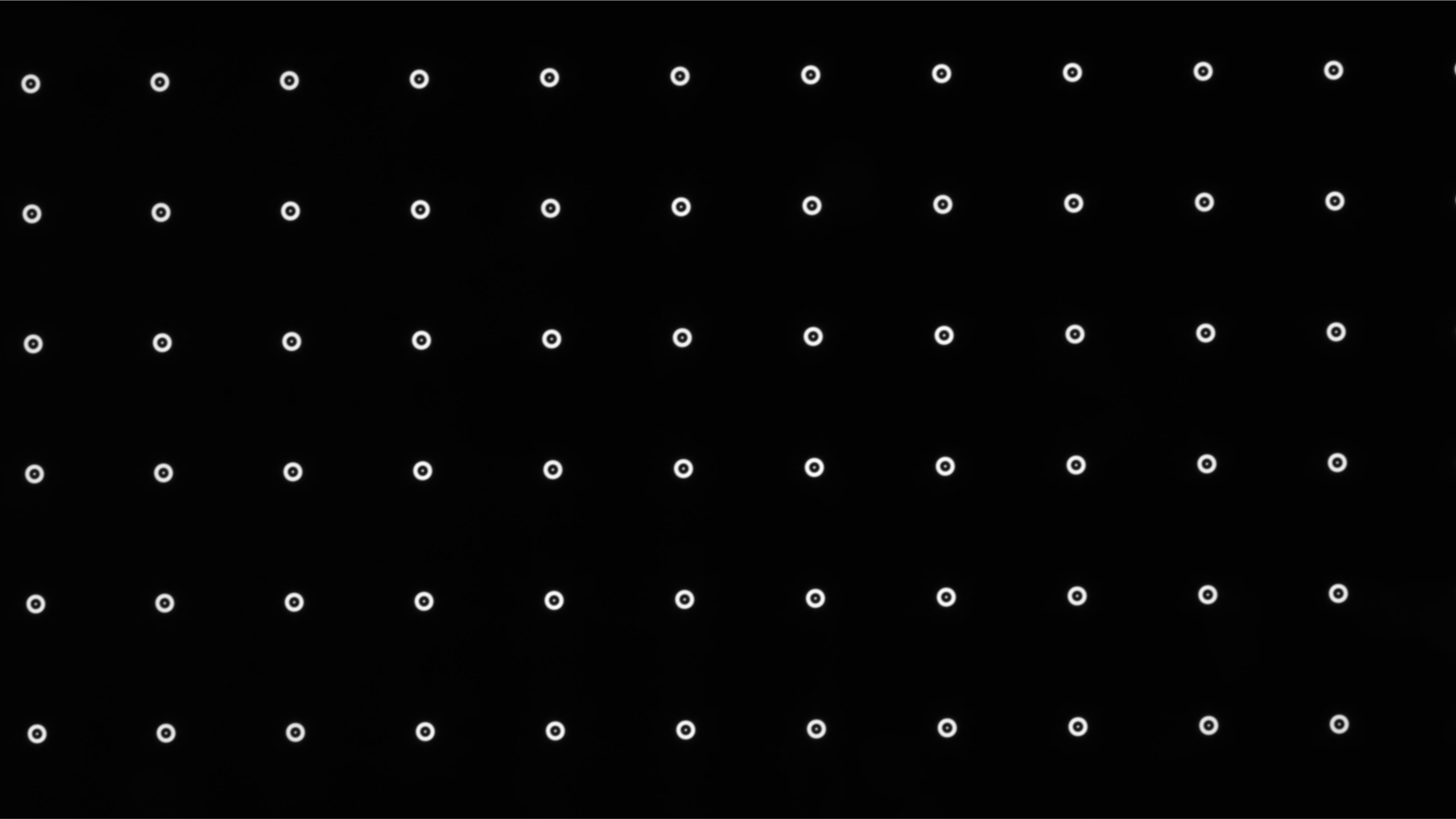

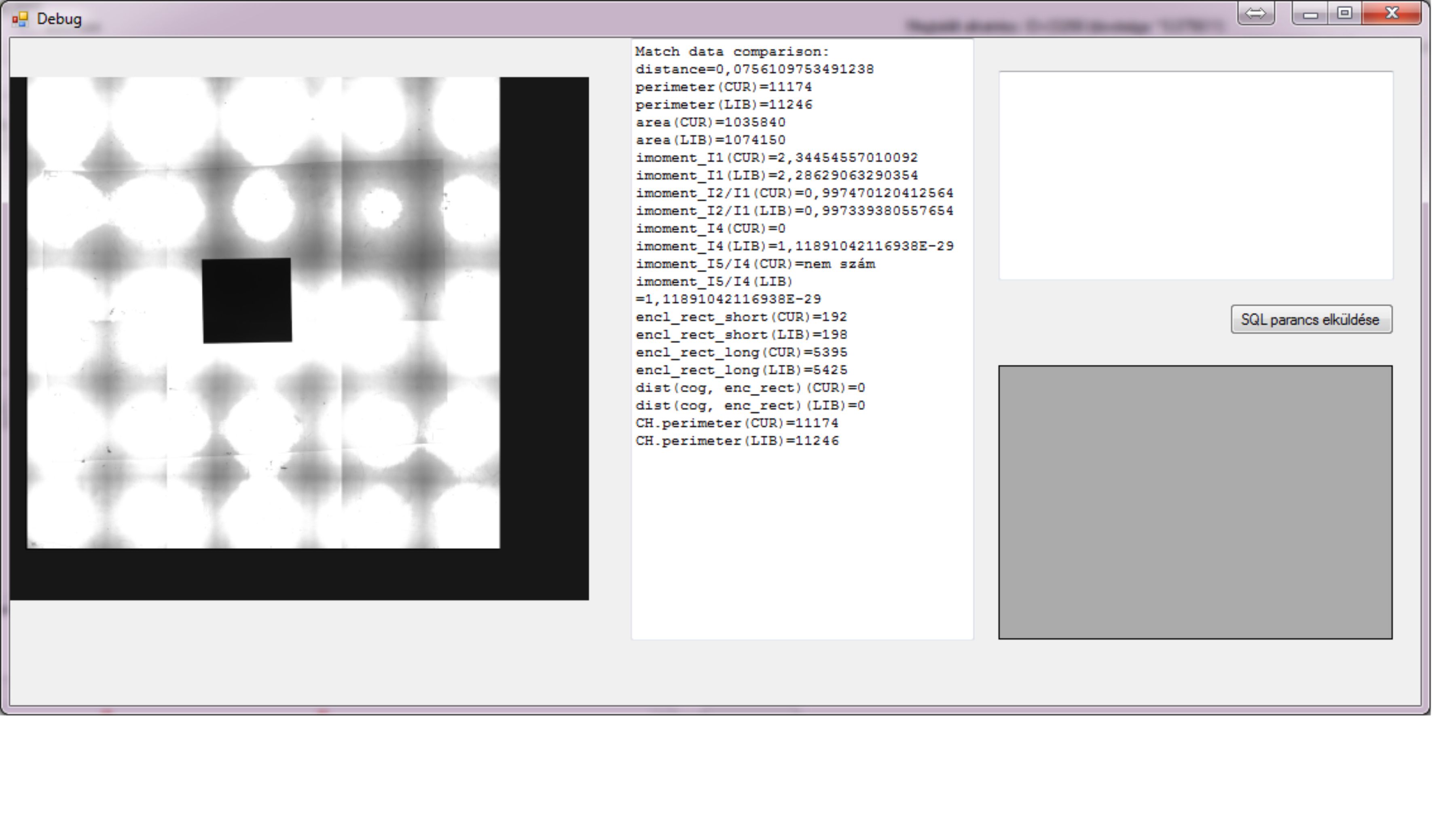

The completed parts are placed on an illuminated glass plate, which is conveyed to the device by a special conveyor belt, but in smaller operations, the feeding can be done manually. The essence of the device is not the feeding system. Inside the machine, a multi-camera measurement system can identify the part by recognizing the contour lines, and the laser point matrix generator and an integrated scale measure the material thickness and weight. The machine also marks the part with a code or serial number using a specially modified laser engraver.

Based on the measured data, the computer, using special software, determines which part it "sees" and whether its parameters match the data obtained from the enterprise resource planning system. By comparing the received and stored information, it checks the quality and quantity of the parts and provides feedback to the control system.

In the project, the optical tasks are performed by Optimal Optik Kft., and the mechanical work is carried out by Meleghegyi és Társa Kft., with the first devices also operating at their site.

Project Information

- Project ID: GINOP-2.1.1-15-2016-00866

- Project Title: Research and Development of Intelligent Optical Sheet Metal Part Recognizer and Laser Marking Device

- Project Completion Date: 2018.03.31.

Funding Scheme

The project, GINOP-2.1.1-15-2016-00866, with a total development cost of 285.7 million HUF, is implemented with the help of 180 million HUF European Union support within the Széchenyi 2020 program.

Fields of Science

- Engineering and Technology

- Materials Engineering

- Optical Engineering

Participants

- Optimal Optik Kft.

- Meleghegyi és Társa Kft.